I’ve tried to report the issue to Prusa support but they keeps trying to diagnose it as user error. But at this point I’m at a loss and presume that it’s either a firmware issue or a sensor issue on my unit.

Either way im very disappointed.

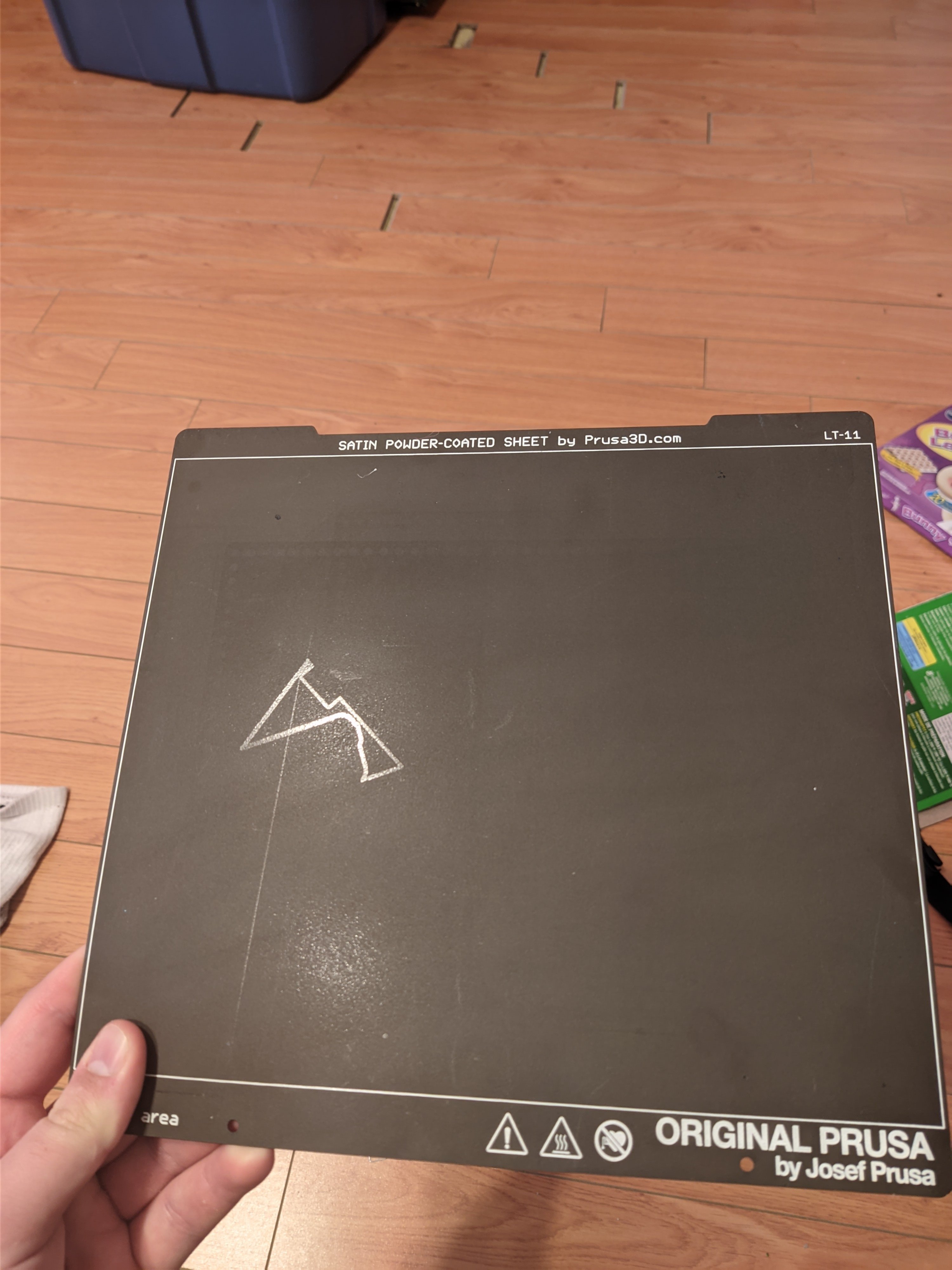

And before you ask, this is the opposite side

EDIT: I will note that this print sheet is ruined for my use case, since those patterns will be shown on the underside of my prints. But the print surface still works and can be used without issue… if you ignore the gouges that are being detailed into every print.

What is going on with your flooring my guy

Living in a 30 year old apartment for 5 years and no way to do repairs. It was liked this when I moved in.

$1,500 CAD/Month (current market $2000) Welcome to Halifax, NS!

If it’s a floating click together floor…Packing tape.

Put like 6 layers down long ways on the board with a foot or so sticking up to use as a handle.

Hold the tape, and kick the tape where it just starts to go up. If done correctly, it will scoot the board along in the direction you kicked. Repeat until gap is now at edge of room, ideally under baseboard and invisible.

I’d just shove some wood filler in the gaps to at least have a smooth floor even if it doesn’t look great. I feel like I’d stub my toes on that shit all the time.

I use some wood filament pla and custom print filler blocks 😉

Bed leveling error

I upgraded my school’s MK3s to MK3.9s, and while it hasn’t gouged in the actual printing area, it has left a deep mark where it first extrudes a line of filament, on all of my sheets.

My problem is kind of the opposite, I feel it doesn’t give it enough squish, and I’m having a lot of adhesion issues. There is also a new cold draft in the space however, so can’t yet pinpoint the issue to this.

I’m sorry to hear they aren’t taking this seriously. I have to use a gluestick on all of my prints with my PEI sheet on my Mk4 and I’ve really been excited to try the Satin sheet as I’ve heard it’s an excellent workhorse sheet for the Mk4. I’m just waiting until I need to order some prusament so I can bundle the satin sheet as prusa shipping costs to the US are steep. Hoping there is a firmware fix for this before I proceed.

Print sheet works, cosmetically it doesn’t. I sell my prints, and having odd lines is not something I want to sell. I’m just disappointed since there was nothing I can do except watch and kill it as fast as I can.

I caution you to not put too much stock into OPs anecdotal experience. This is not a problem other people are having and is certainly not a firmware issue. I can say for certain that it has never happened for me.

I just had to read up on the MK4 because I don’t own one. Apparently this machine uses a load cell on the bed to detect the nozzle touch? That means that to home Z or mesh level the bed, the nozzle has to touch the build surface. This strikes me as a rather bad idea. I can think of tons of situations such as a pointy diamond or ruby nozzle, a very hot nozzle, or a nozzle with hardened crud stuck to it all causing damage to the print sheet, not to mention the potential for damage to the nozzle itself.

Ideally the nozzle should never, ever touch the print surface. For any reason.

There’s a purpose behind things like the BL Touch having a soft plastic probe on the end.

In the cases you describe it should fail by ruining the print, not the build plate though. If there is something between the nozzle and the plate, it will be too far away from it after calibration, not too close.

If you’re bed leveling with a heated nozzle, you’re not doing it right.

Shouldn’t you make your adjustments while the bed and nozzle are at least partially heated, since metal expands when heated? If you adjust z-offset when cold, the nozzle may expand a bit, decreasing the gap. At least that’s my understanding, and why most printers I’ve seen will preheat the bed and nozzle before doing bed leveling

Sure, but that doesn’t mean there won’t ever be some situation where it’ll try to Z home for whatever reason, or even if it’s just user forgetfulness, and you poke the PEI sheet with a 215+ degree nozzle. The fact that the mechanism inherently includes that possibility is stupid.

The printer won’t do any leveling with a fully heated nozzle.

The MK4’s we use at work and my personal MK4 all heat up to 170 before bed leveling, and if you previously swapped filaments before leveling, the printer will pause and wait until the nozzle has cooled down to the target range before initiating bed leveling.

Well, then at least they thought of that. Will it Z home with the nozzle preheated? I’ll bet you it will.

Josef letting us down!

As he is wont to do. I hate that idiot.

If this was during an auto level, it’s my humble opinion that this is a manufacturer’s defect in the machine that caused the damage. There should be proper coding to ensure that any increase in sensor pressure by (delta p) halt that machine and that there should be a pressure offset in the sensor such that a loss of signal or anomalous zero reading or lack of reading is done prior to levelling to ensure that a sensor failure has not occurred. My XL freaks out if a fan isn’t spinning at the right speed, so they clearly know that a nominal operational check before the print starts is proper engineering design.

Of course you won’t get anywhere. Unfortunately, a lot of 3D print failures really are user error so I suspect that’s their default response and it takes them a good deal of proof to push them of that mark.

I 100% agree, however I went Prusa for their replacement parts and long term support of said parts. Rather than their quality which outside of the bed levels on uneven surfaces has been good.

Oh, I didn’t mean to come off as dissing Prusa in general. I ponied up for an XL and it’s night-and-day better than any previous printer I’ve owned.

Dem Barney toes