I do a lot of soldering and for the last few years have been using SMD components. Up until recently I was buying short pieces of tape with a few dozens or a hundred components. The amount that I do has really increased and running our of components began to irritate me so I started buying them on commercial rolls of 4,000 or 5,000 components.

The full rolls are unwieldy so what I really wanted was a cartridge that was small enough to have a bunch of them in a drawer or plastic storage box but big enough to hold a fair number of components.

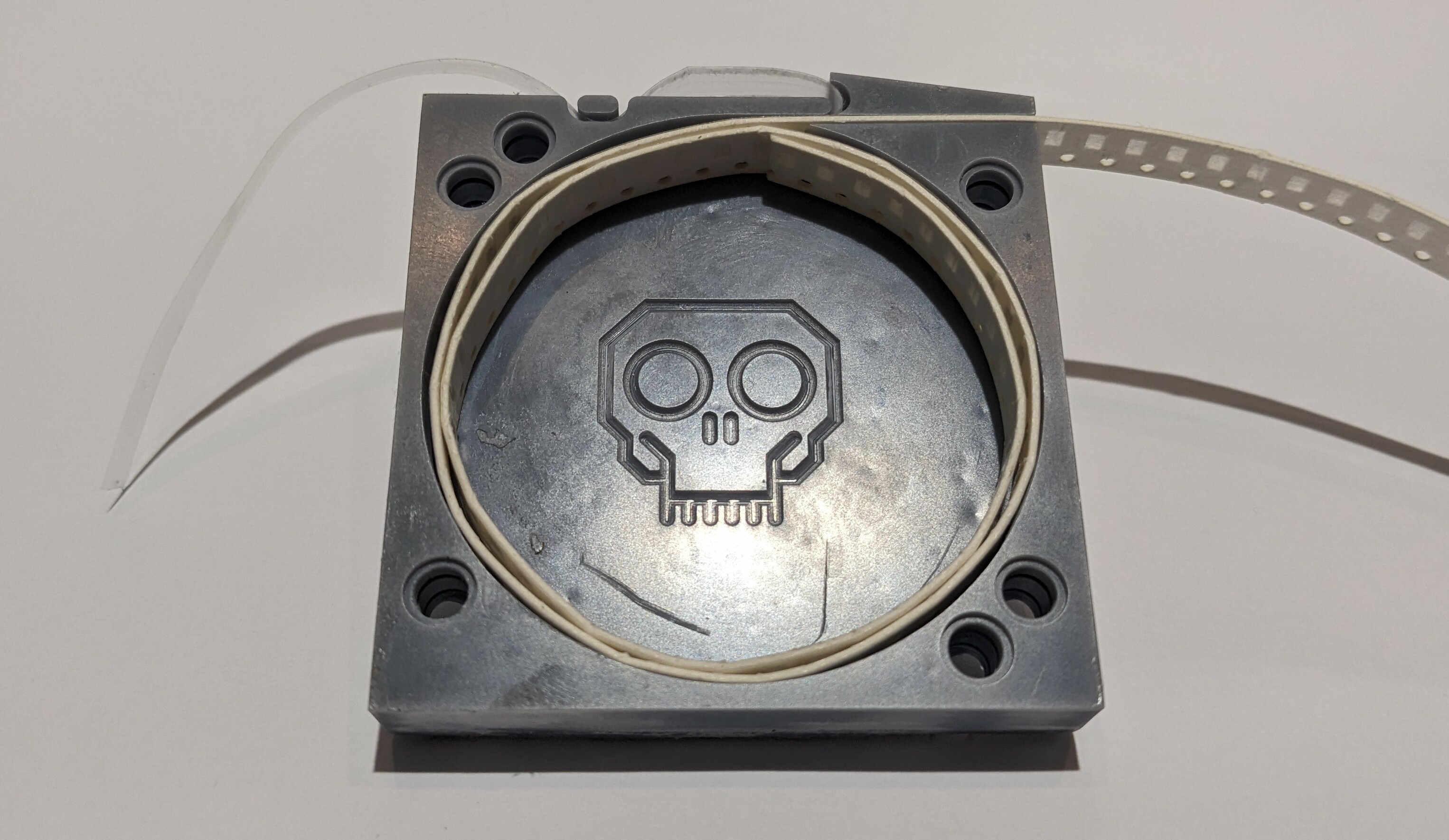

So…I designed this.

It’s 60mm x 60mm x 11mm and is designed to dispense standard 8mm x 1mm component tape. I’ve got other versions for wider and thicker tape. It will hold a good 2m or tape which is around 1,300 components. The paper tape with the components comes out the straight slot while the clear plastic cover tape turns back out of the curved slot. The little tab holds the cover tape back so it doesn’t get in your way. The splitter between the straight slot and the curved slot keeps the components from falling out until the tape emerges from the straight slot.

I think that the coolest feature of this design is the holes around the corners of the cartridge. They allow you to gang cartridges together into stacks using standard LEGO Technics connector pins. The cover also uses connector pin like projections to attach to the cartridge. With the cartridge being only 11mm thick you can’t put two pins end to end so I needed two holes so that the pins in adjacent connections can alternate which hole they use. On 16mm and wider cartridges I could have used a single hole but will keep the two holes for compatibility with the narrower cartridges.

This is a rough prototype to test the fit of the tape. It seems to work quite well.

I know OpenPnP. We have talked about it but most of the work I do is very small run. I hand solder everything down to 0402s and TQFPs with 0.4 mm pitch in one to three or four units. I've considered buying a hand PnP unit and I may at some point. I just upgraded to a new Hakko dual head soldering station which makes hand soldering stupid easy. I've probably got a few years of hand soldering in me.

Most of what I do is repairs and rework with a fair amount of prototyping.

For any production runs the guys I work with have PCBWAY do the populating for them.

Ah, I haven't had to do SMD repair in a long time so it totally flew over my head. Those tweezer soldering irons are gooooood stuff. So much faster to remove tiny little caps and resistors.

Tweezers are the bomb. I've been doing a lot of repairs to old gaming consoles and hand helds. That actually paid for the new soldering station. Removing the surface mount caps without tweezers is possible but not easy.