Same issue, been going on for months now. I read somewhere that it has to do with the Jerboa client and an upcoming update is supposed to fix it…

Same issue, been going on for months now. I read somewhere that it has to do with the Jerboa client and an upcoming update is supposed to fix it…

For the person who just can’t part with anything…

I think it’s “Ze German” in me that wants to build a printer from scratch lol. That, and 350x350 core xy sounds like fun. I need to have at least three unfinished projects going at once to feel sane 🤣

Firmware is closed, yes. Bambu’s slicer is just a skinned version of Prusaslicer though. Which, tbh, is kind of scummy lol.

At some point I’ll take the Voron plunge, but for now I’ll just watch my p1s shake all over the place on its silly rubber feet 😂

Having finally seen a Prusa in action, I would have to say they’re both great printers (I have a p1p that I upgraded to a p1s). I understand the arguments against Bambu, but honestly if you’re not printing anything overtly illegal or truly creating things you plan on copyrighting, you’re fine, and if you are that paranoid, you can remove the tape behind the front faceplate and simply unplug the wifi antenna and just print from the SD card, just save in .3mf

Think of the two as Android (Prusa) vs Apple (Bambu). Both will do the job just fine, just depends on which ecosystem you prefer.

I’ve heard nothing but good things about these, if I didn’t have a Bambu I’d definitely look into getting one

I ran into this with my e3v2 a LOT. Are you heating up the bed and nozzle before you level? You may have answered that and I missed it. Also, I’m not sure how well those silicon things work, I did the “yellow springs” and then make them all equally tight, then level by loosening. Another thing to check- is your build surface flat? Check when cold and hot. My glass bed wound up warping up near the middle ever so slightly and that would be enough to make a batch of moms spaghetti. I was able to get it working well for a while, then it somehow shit its pants into the silicone sock and mucked up the whole hotend with nice black pla+.

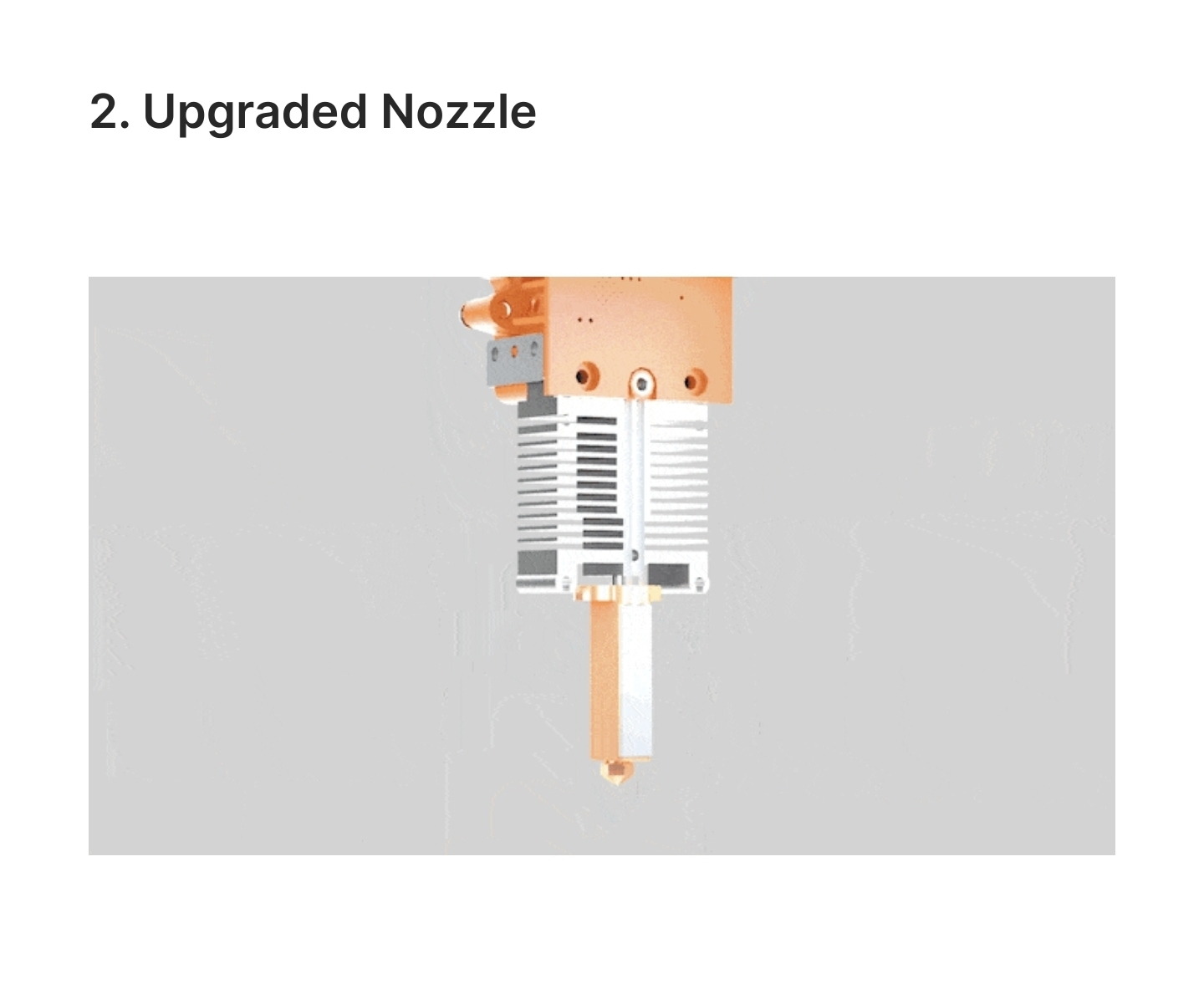

Looks like a Bambulabs nozzle/hotend…

Gonna "both sides" this one…

I've never used a prusa printer, but know two people that swear by them. I know 2 with P1P's (including me)and one with an X1C. I can attest that it's a great printer.

Now, the open source nature of the Prusia is the clear winner in the privacy arena, but ask yourself if the rest of your network/hardware is as locked down as you want your printer to be? I'd be willing to bet a surprising number of people who tout this as their number one concern about BambuLabs printers are using Windows.

Also, you can print just fine using other slicers and dropping your files on an SD card, never having to connect your printer to the internet at all with the Bambu printers. But they do sort of lead you down the networked path without expressly telling you that it will work offline.

Not going to get into specs, price or any of that shit, just saying both printers are great and more than capable of what the majority of FDM users want from their machines. I'd love to go Voron all the way, bit I do not have the time to commit to the building/calibration or testing.

Tl;dr… this doesn't need to turn into a bloods vs crips argument about which printer is better

I just took the dive on a P1P and you can print offline using an SD card just fine, it’s just not really pointed out. My E3V2 served me well over the years but the Bambu is a game changer

Agree 100% as a e3v2 owner. Regardless of what printer you get, it WILL break/lose calibration/dumbfound you at some point, at which point you will either be throwing time or money at it, or both. My suggestion would be to get the best reviewed and most popular printer that fits your expected maximum build volume, as there will be a larger user base to help you when something does go wrong, and despite what several people here have said, I’d avoid used at all costs until you have some experience under your belt and know what you’re looking for. As another commenter said, if you truly are o ly going to break it out occasionally, there really isn’t a need to drop a ton of money on one, you can get acceptable quality relatively cheap nowadays.

Why does this remind me of that old “you wouldn’t download a car” commercial???

Nice job though

I love practical prints, so much better than “check out this character bust!”, especially when you designed it yourself. Currently making soundhole covers for cigar box guitars and trying to figure out a good way to spray DIY conductive paint on them to nickel plate. Whenever I get it figured out I’ll post but so far nothing to write home about.

A agree with what was said above, but I have to add that if you decide to go with direct drive you’ll also need to take the time to dial in your retraction distance and speed in your slicer. When my E3V2 stock extruder teeth wore out, I went all in and got a Microswiss NG direct drive extruder/hotend. If you don’t dial in your retraction distance and speed you will likely get tons of ooze. You’ll also need to recalibrate pretty much everything from your z offset, e-steps, input shaping if you use kilpper, belt tension… the works. Is it worth it? That depends. In my case, yes it was, buy ymmv

Why first fdm, then resin? If you want resin printer just go that path. Resin is good for miniatures while filaments are better for mechanical properties and bigger size. Fdm is faster, but still extremely slow. For 20x20x20 cm model you need like 1 day or more to complete. Get something that supports klipper firmware, like ender (probably most cheap printers) and expect extra cost on upgrades.

^this, verbatim. My advice is, think about what it is you want to print and go from there. If you’re going to try to make functional parts with the occasional “cute” gift for someone, chances are you’d want to go with FDM and Fusion 360, then it’s dealers choice on which slicer you prefer. Then think about what you’re using those parts for, and figure out what filament will be best for that part, whether it needs to sit in a hot car, for example, you’ll be looking at ABS / ASA versus something that sits inside on a desk and doesn’t need to support weight, where PLA is your cheap and generally easiest filament to use. Then, research what printers are capable of printing said filament, as not all 3d printers can handle higher temps, need enclosures, etc.

On the other hand, if you’re going to make tabletop miniatures or need the properties of resin for whatever reason, you’ll want to go with resin, and modeling software such as Blender as others have suggested

I think it’s a good added measure to stop a print, in this case something caused the spaghetti, it would have kept causing spaghetti but the cover popping off stopped the print. I’ve got about 400 hrs on my p1s (upgraded from p1p), and I’ve never had the faceplate pop off. I would guess this is an isolated incident.