Thank you everybody for leading me on the right path.

As I had already installed Klipper, I decided to try the pressure advance calibration as suggested and it did take some tuning, but has improved quality immensely.

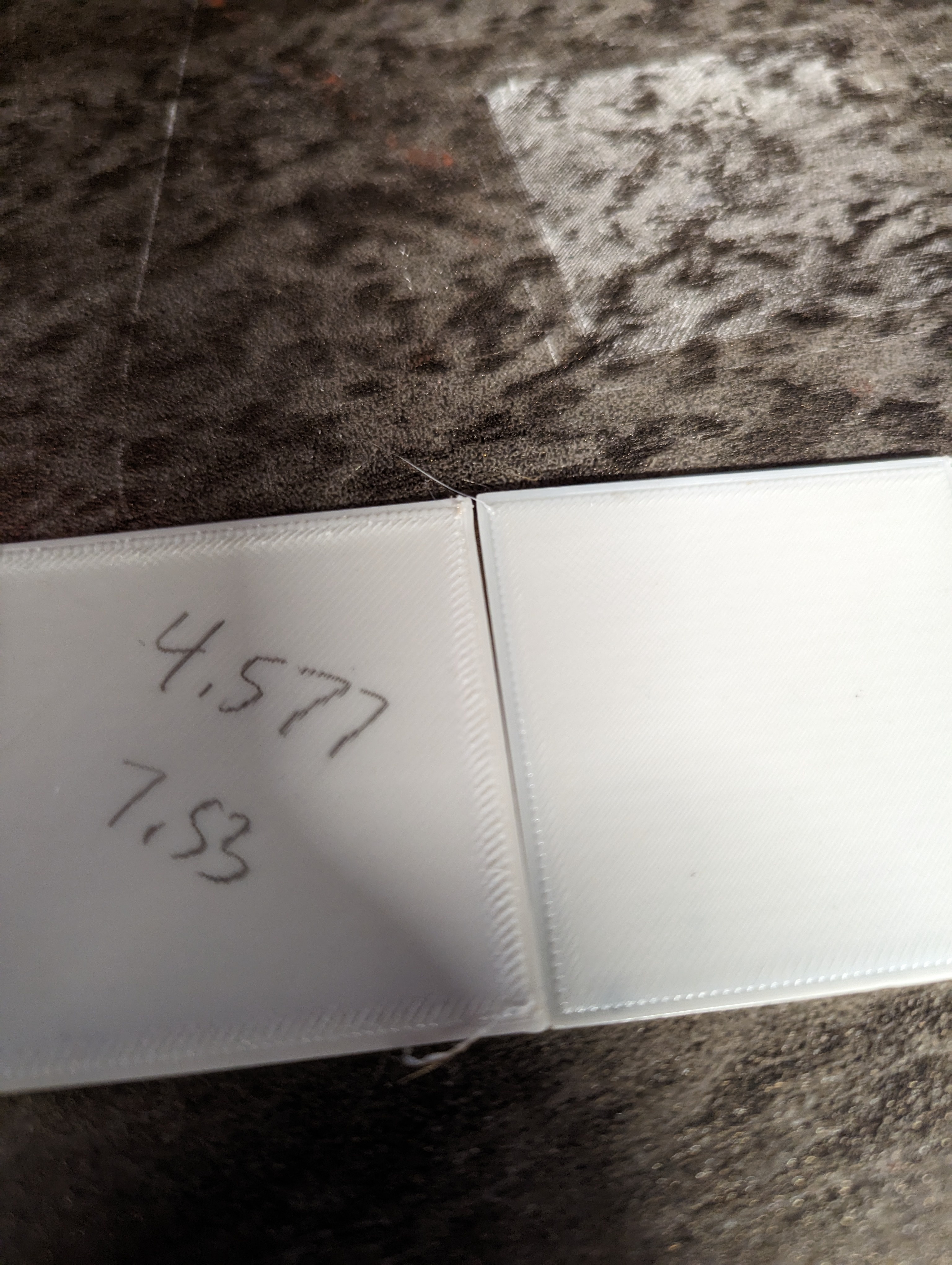

In the end, here are the settings I changed: Klipper printer.cfg pressure_advance: 0.120

PrusaSlicer:PrinterSettings:Extruder 1:Retraction Length: 0

I still think I can tweak my z-offset and temperature and maybe further refine pressure_advance, but the results are quite a bit better than before.

I used the Klipper guide for pressure advance: https://www.klipper3d.org/Pressure_Advance.html

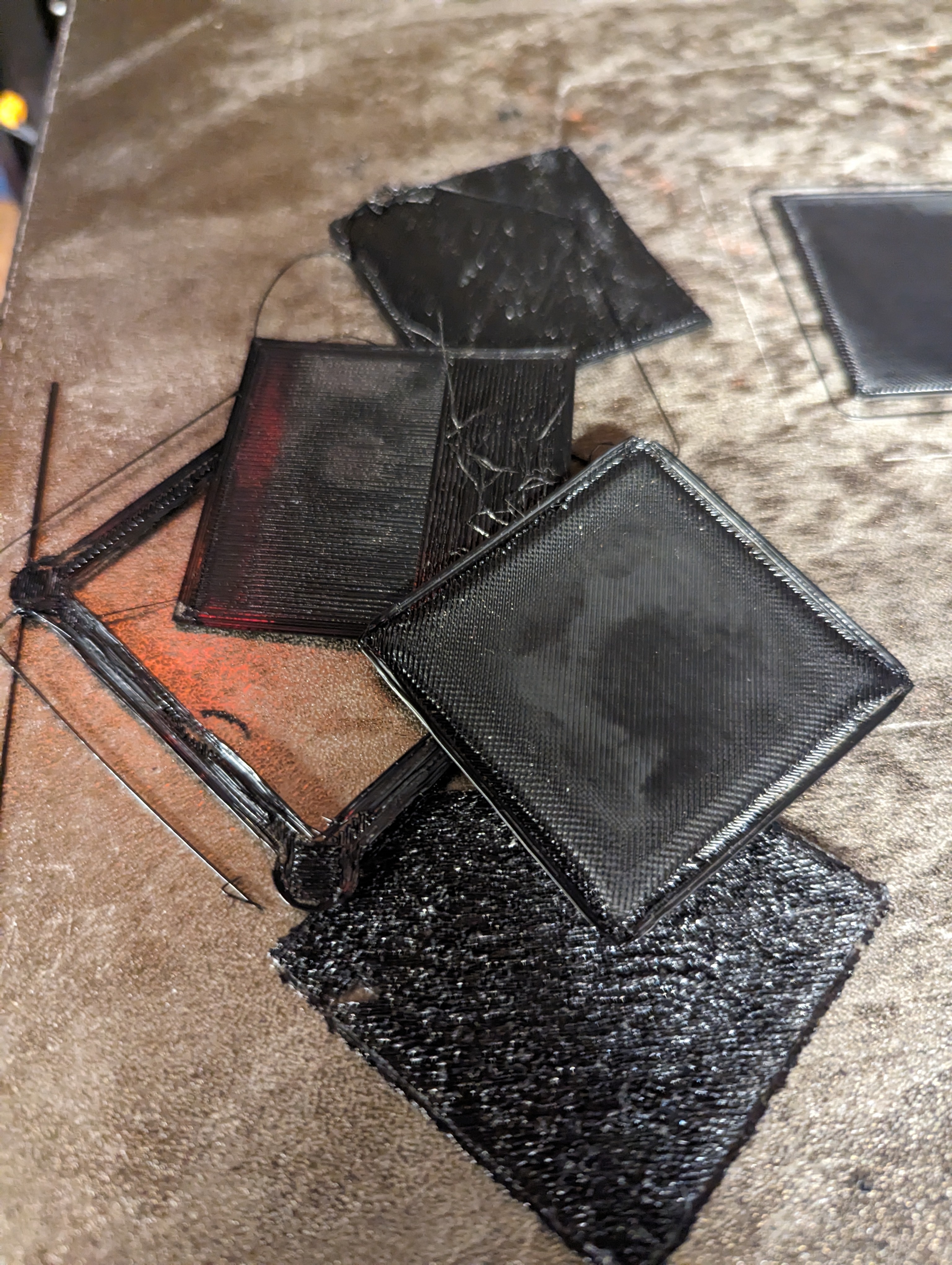

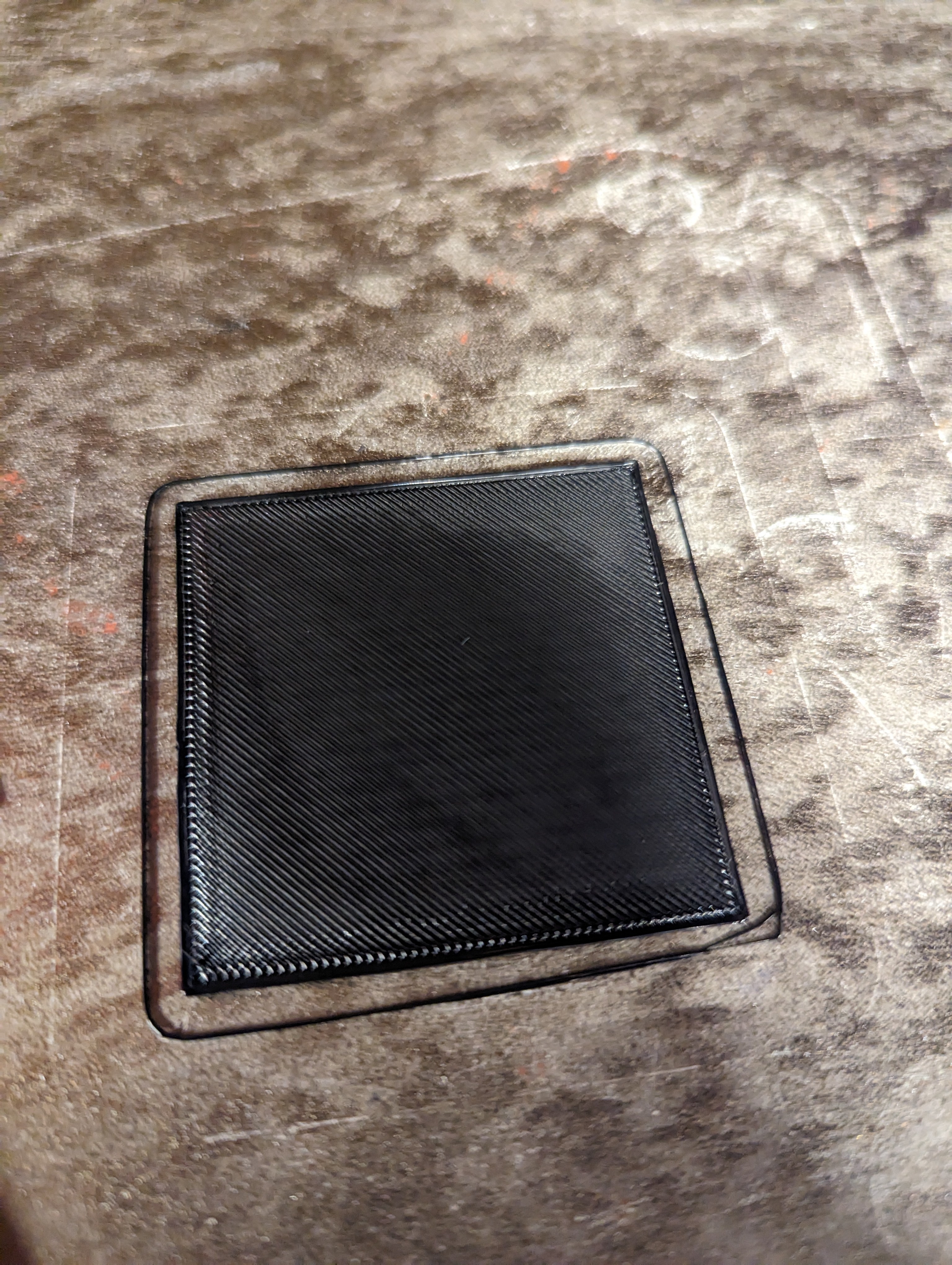

Original print on the left, print with the above changes on the right.

Having said that, I think I might have been able to improve the results using a marlin firmware and working with my retraction setup – I use a non-default direct-drive extruder so the default settings of about 6mm are certainly incorrect.

Also, into the future, i’ll check out the wear/maintenance on the nozzle – it is a good point and I havent changed it in quite a few prints.

Thank you everybody!

So, I bought myself a rpi4 and installed Klipper. Very cool firmware quite enjoying it. Still tuning but i’ve got my speed up 3x from my Marlin based firmware. I think I’ll continue looking at the options here recommended and build one – mostly because I want to – not because I am solving a problem. Thanks for putting me onto Klipper.